HYK

SPC(Stone Plactic Composite) flooring is a new type of floor decoration material developed through high-quality and high-tech research and development, and has gradually become the mainstream product in the floor decoration material market. This article introduces the development overview of SPC flooring, discusses its application in combination with technical and process characteristics, and provides an overview of its future development trends and how to select SPC flooring products.

1. Overview of the development of SPC flooring at home and abroad

From the perspective of application, the main application fields of SPC flooring in China are hotels, shopping malls, schools, etc., and the application proportion in the household field is less than 5%. However, in developed countries and regions such as Europe and America, the proportion of SPC flooring in the household field has already approached 10%. However, domestic data in recent years shows that from 2017 to 2019, the production and sales of SPC increased at a rate of 10% year by year. In 2020, the domestic market experienced explosive growth. The vast majority of the top 100 domestic real estate enterprises accepted SPC flooring products and selected them in architectural design. From the perspective of industrial policies, compared with floor decoration materials such as solid wood and tiles, SPC flooring is more in line with the concepts of green environmental protection and resource recycling. It is an industry supported by national policies, and the relevant support policies include the new version of "National Key Supported High-tech Fields", "Guiding Opinions on the Development of the Building Materials Industry during the 13th Five-Year Plan Period", "Guidelines for the Development of the New Materials Industry", etc. From the perspective of consumption concepts, the improvement of consumers' environmental awareness and health awareness has led to a gradual increase in the application of SPC flooring. Moreover, SPC flooring also has strong decorative aesthetics, which can meet consumers' personalized demands and effectively promote the growth of their consumption.

From the perspective of the development of downstream industries, the real estate industry and the building decoration and renovation industry are the downstream industries of SPC flooring. The improvement of urbanization level has brought a continuous and large market demand to the SPC flooring industry. The annual increase in the sales area of commercial housing in China has led to a continuous growth in the demand for architectural decoration and renovation in the country. Therefore, SPC flooring has a huge application market.

2.SPC flooring technology and Process Flow

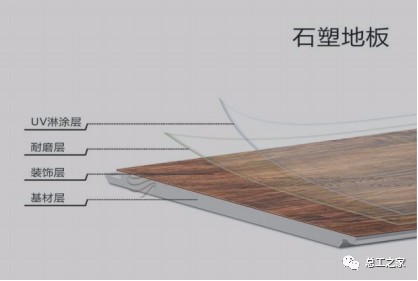

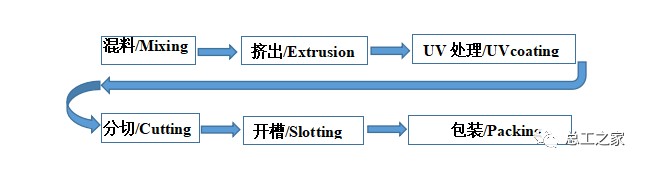

SPC flooring is a product made by extruding PVC base material through an extruder combined with a T-shaped die. The PVC wear-resistant layer, PVC color film, and PVC base material are then thermally laminated online using a three-roll or four-roll calender. The process is simple, and the lamination is completed by heat without the need for glue. SPC flooring materials use eco-friendly formulas and do not contain harmful substances such as heavy metals, phthalates, and methanol. They comply with standards EN14372, EN649-2011, IEC62321, and GB4085-83.

The production process of SPC flooring is as follows

3. Characteristics and Applications of SPC Flooring

Compared with other floor decoration materials, SPC flooring has incomparable advantages

3.1 Green and Environmental Protection

The main raw material for producing SPC flooring is high-quality polyvinyl chloride resin, which is an environmentally friendly, non-toxic and renewable resource. It is natural and eco-friendly, 100% free of formaldehyde, benzene, heavy metals and carcinogens, soluble volatile substances and radiation.

3.2 Ultra-light and ultra-thin

SPC flooring is only 2-3mm thick and weighs only 2-3KG per square meter, which is less than 10% of that of ordinary floor materials. In high-rise buildings, it has incomparable advantages in terms of floor load-bearing capacity and space conservation. At the same time, it has special advantages in the renovation of old buildings.

3.3 Super Wear-resistant

The surface of SPC flooring is coated with a special transparent wear-resistant layer processed by high technology, which fully ensures the excellent wear resistance of the floor material. The wear-resistant layer on the surface of SPC flooring can be used for 5 to 10 years under normal circumstances depending on its thickness. Due to its extremely strong wear resistance, it is suitable for application in places with large foot traffic such as hospitals, schools, office buildings, shopping malls, supermarkets, and transportation vehicles.

3.4 High elasticity and super strong impact resistance

SPC flooring is relatively soft in texture, thus having excellent elasticity. It can recover its elasticity well under the impact of heavy objects, providing a comfortable foot feel and is thus called "soft gold of flooring materials". At the same time, SPC flooring has strong impact resistance and can recover its elasticity effectively from the damage caused by heavy objects, without causing any damage. When people walk on SPC flooring, compared with traditional solid wood flooring and laminate flooring, it can significantly reduce the impact force on the feet and lower the proportion of people falling and getting injured.

3.5 Super anti-slip performance

The wear-resistant layer on the surface of SPC flooring has a special anti-slip property. Moreover, compared with ordinary floor materials, SPC flooring feels more rough underfoot when it gets wet, meaning that the more water it gets, the better its anti-slip performance becomes. Therefore, it is suitable for public places with high public safety requirements, such as airports, hospitals, kindergartens, schools, etc.

3.6 Fire Resistance and Flame Retardancy

The main component of PVC plastic flooring, polyvinyl chloride, is difficult to burn and can play a certain flame-retardant role to a certain extent. According to the standard "Classification of Fire Performance of Building Materials and Products" (GB 8624-2012), plastic flooring is classified as a flame-retardant material (with a fire resistance index that can reach B1 grade). SPC flooring itself does not burn and can prevent combustion, and it does not produce toxic and harmful gases that cause breathing.

3.7 Waterproof and Moisture-proof

SPC flooring, whose main component is vinyl resin, has no affinity for water. Therefore, it can be used in damp environments and will not mold due to high humidity.

3.8 Sound Absorption and noise reduction

SPC flooring has a sound absorption effect that ordinary floor materials cannot match. It can absorb up to 20 decibels of sound and is suitable for use in hospital wards, school libraries, lecture halls, theaters and other places, providing a more comfortable and humanized living environment.

3.9 Simple installation and convenient maintenance

A good utility knife is sufficient for arbitrary cutting. It can also be combined with materials of different patterns to meet consumers' diverse and personalized decoration needs and achieve the most ideal decorative effect. Moreover, the installation and construction of SPC flooring do not require the use of building materials. Only environmentally friendly floor adhesive is needed for installation. The maintenance of SPC flooring only requires regular waxing or daily cleaning, and the maintenance frequency is much lower than that of traditional flooring materials.

3.10 There are a wide variety of colors and varieties

SPC flooring comes in a wide variety of patterns and colors, such as carpet texture, stone texture, wood floor texture, etc., and even personalized customization can be achieved. The patterns are realistic and beautiful. Combined with a variety of accessories and decorative strips, they can create an absolutely stunning decorative effect.

3.11 Resistant to acid and alkali corrosion

The surface of SPC flooring has undergone special protective treatment and has strong resistance to acid and alkali corrosion. Therefore, it is very suitable for application in hospitals, laboratories, research institutes and other places.

3.12 Heat conduction and warmth preservation

SPC flooring has excellent thermal conductivity, uniform heat dissipation, and a small coefficient of thermal expansion. Therefore, it is more suitable for home paving, especially for geothermal heating floors in the cold regions of northern China.

4.The future product development trends of SPC flooring

4.1 Antibacterial SPC flooring

Due to the continuous improvement of people's living standards and the constant strengthening of health and environmental protection awareness, especially under the influence of epidemic diseases such as influenza and COVID-19, consumers are paying more and more attention to and attaching importance to their home environment. Antibacterial flooring is made by adding a certain amount of antibacterial agents to floor materials and processing them to form antibacterial flooring. This can inhibit the reproduction of surface bacteria, thereby achieving the goal of long-term hygiene and safety.

4.2 Electric heating SPC flooring

Electric heating flooring is made of nano-carbon crystal molecular heating core materials. Under the action of microcurrent, the core materials vibrate and rub against each other to generate heat and release it into the room. The electric heating conversion rate is over 96%, which is highly efficient. The electric heating flooring has excellent performance in terms of pressure resistance, water resistance, and insulation. Even when working in an extreme environment, it is less likely to cause safety accidents. The thermal efficiency of the electric heating floor is high. Its heat can be well maintained within the range that benefits the human body, and the loss during heat transmission is very small.

4.3 Lightweight SPC flooring: The lightweighting of the flooring ensures that its performance remains unchanged. Through processes such as foaming and co-extrusion, the weight of the flooring is further reduced, thereby lowering transportation and installation costs.

4.4 SPC flooring with new dimensions that meet the requirements of the new installation plan

In addition to the tradition-sized flooring, more new sizes of SPC flooring such as 300*600 and 600*600 are constantly being developed and used to meet the personalized market demands, and the applications of the products are also becoming more extensive.

4.5 Wood (bamboo) veneer SPC flooring

Wood (bamboo) veneer SPC flooring is based on SPC formula, with wood (bamboo) veneer covering the surface, and then undergoes surface treatments such as wear resistance, water resistance, and anti-aging. This way, it not only retains the natural texture of wood (bamboo) materials, but also the product possesses all the advantages of SPC flooring, making it an ideal floor covering material.

4.6 SPC flooring produced by 3D printing equipment

With the maturation and improvement of 3D printing technology and the rapid development of the trend of personalized demands for floor products, the advantages of 3D printing technology, such as customizability, the ability to print any color and pattern, and the ability to print wide products, have met market demands and achieved rapid development.

5. Methods for choosing high-quality SPC flooring

5.1 The product must pass important national testing and certification.

For instance, ISO9001, ISO4001 quality certification system [13], Chinese national standard, and Chinese metrology certification. In addition, the floor score certification of the United States, the safety certification of the European Union, the green environmental protection certification, the SGS international authoritative certification, etc. are all stricter standards that are widely applicable worldwide.

5.2 Attention should be paid to all the indicators of physical and chemical properties.

All products must undergo sampling inspection before leaving the factory. Only those that fully meet the standard requirements are qualified products.

5.3 Pay attention to the appearance quality of the product and the uniformity of its specifications and dimensions.

High-quality SPC flooring has excellent flexibility. Even if it is twisted and bent at will, there will be no cracks or breaks on its surface. The dimensions of each board must meet the requirements. If the deviation is too large, it will inevitably cause uneven seams and deformed patterns, thereby affecting the overall decorative effect.

5.4 Attention should be paid to the differences in raw materials and manufacturing processes.

At present, the base materials used by domestic manufacturers can be roughly divided into two types: new materials and recycled materials. Good SPC flooring is made of new materials, which are highly elastic, less prone to deformation when soaked in water, less likely to shrink or expand when exposed to cold or heat, and less likely to warp at the edges. 5.5 Special attention should be paid to after-sales service guarantee. The quality of construction is as important as that of the product, affecting the service life of stone plastic flooring.